by Jeremy Stone

Having always had a soft spot for the East Coast Main Line during the 50s and early 60s, and having spent time spotting at Grantham in the 80's with my late grandfather, I decided to model a 'slice of Grantham shed' which would centre around the coaling plant, water tower and coaling stage. The layout would be built to 2mm finescale standards and involve a considerable amount of scratch building and research on the prototype. After much research I stumbled across the fantastic thread on the LNER Forum website Returning to Grantham where one of the members had kindly posted some plans of the coaling plant which was the ideal starting point for this structure. The plans indicated that the tower was approximately 80ft high and from this measurement I managed to calculate all the mesurements for the tower and the feeder floor. There aren't many photos of this structure but several were found online, in books and magazines that I have in my collection. Even glimpses of the tower in photos can provide extra details from which to work with.

The tower was built in 1938 and was operational right the way through to the closure of Grantham shed in September 1963, before finally being demolished in 1964 by explosives.

With this information in hand I set to work drawing out all the parts for each section of the tower on a sheet of 1.5mm thick plasticard. I felt this would be the right thickness as I needed the model to be fairly robust due to its height, which in 2mm scale extends to just over 16cm. Each part was then carefully cut out and fixed into position.

The legs for the tower were built using 4mm square plastic strip and the feeder floor is built from a 0.75mm thick plasticard sheet. The steps which run the full height of the model are pre-made and are trimmed to size to fit each section.

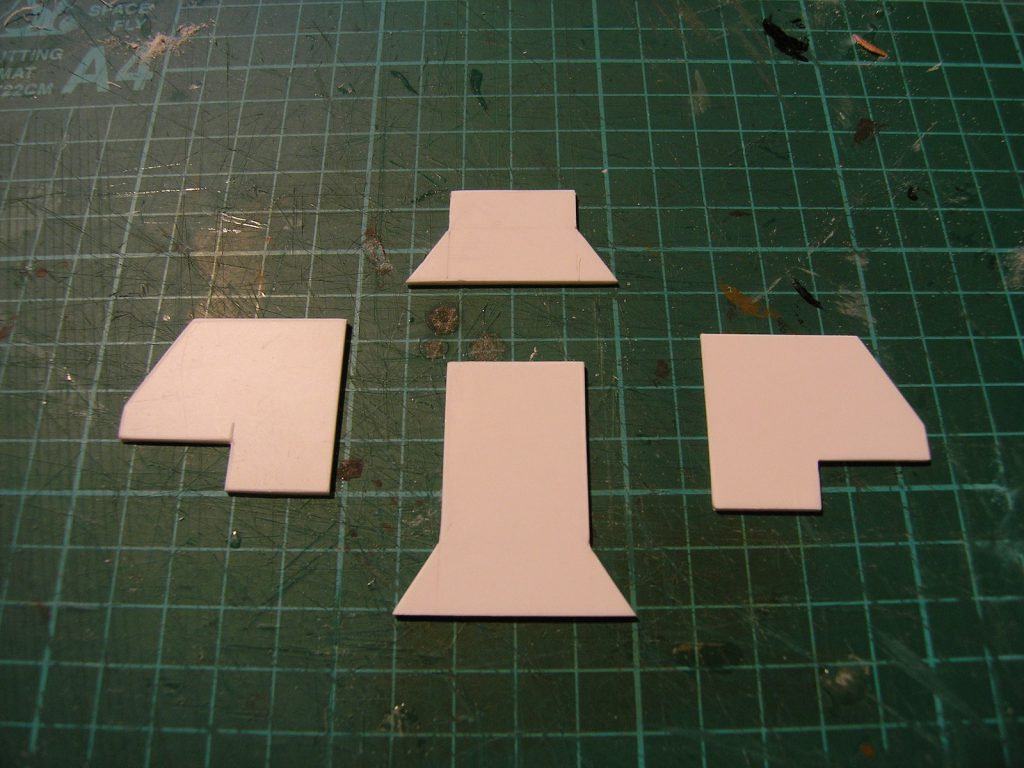

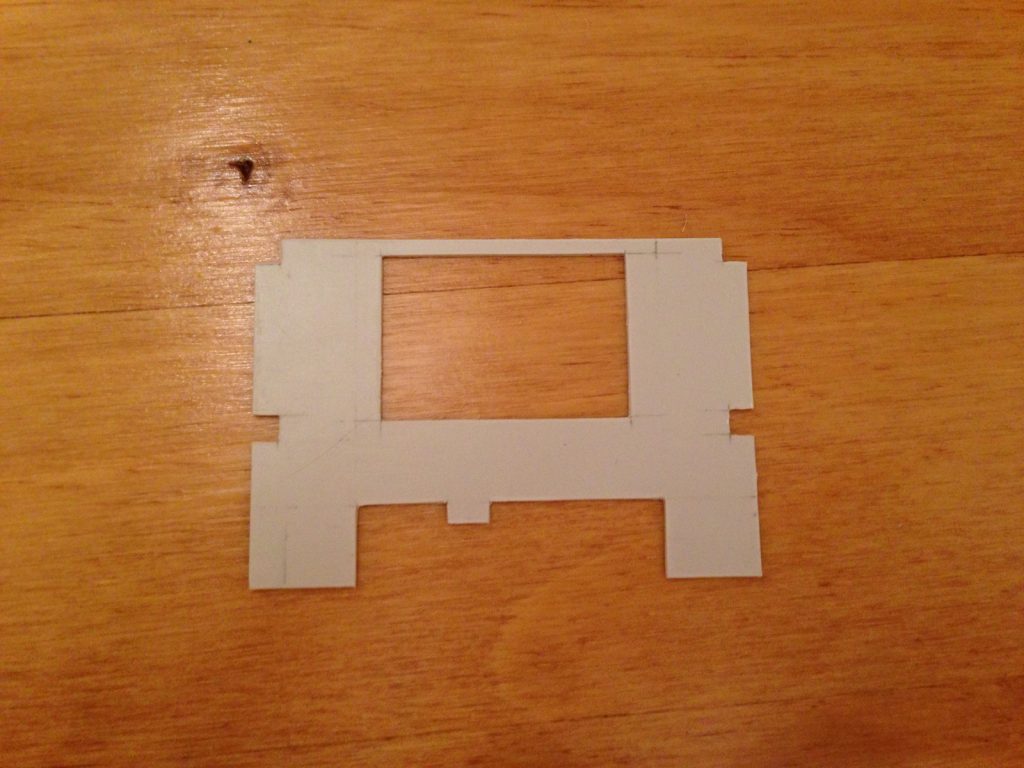

The current collection of photos show the build in various stages, the first showing the parts cut out and ready to be glued together for the top section and then showing it finally taking shape.

There is still plenty to do and the finished model will be the subject of a future article in the very near future.

Photo 1 - Initial parts cut out and ready to be fixed together forming the top section of the tower.

Photo 2 - Parts from photo 1 fixed together

Photo 3 - The tower starts to take shape

Photo 4 - The feeder floor cut out and ready to be fixed into position. The plans came in very useful to get this particular section correctly drawn out.

Photo 5 - Feeder floor in position.

Photo 6 - The current progress on the model, with the majority of steps in position

The plan is to build the coaling plant, coal stage and water tower, so please keep checking back for updates.

Link to Part 2.

Copyright note: the article above is published with the appropriate permissions. For information about copyright of the content of Tracks through Grantham please read our Copyright page